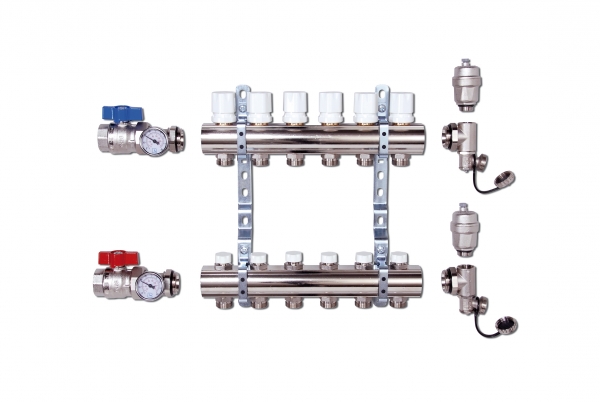

Brass distribution manifolds - CD Series

The CD series manifolds are obtained from drawn brass bar with yellow* or nickel-plated finish.

All manifolds undergo a post weld heat treatment to eliminate any tension caused from processing. Do only use Luxor manifolds with Luxor accessories with soft o-ring sealing.

All of Luxor fittings and accessories for manifolds (such as drain valves, plugs, etc.) are provided with this kind of sealing and do not require the use of any intermediate element (PTFE, hemp, etc.), which could result in cracks. We recommend to tighten the fittings to a maximum torque of 60 Nm.

* In compliance with D.M. 174/2004

Max temperature

120 °C

Max pressure

10 bar

Materials

CW617N

UNI EN

12165:2016

Knob

ABS bianco

RAL 9016

Stem

AISI 316

Testing

100%

TECHNICAL SPECIFICATIONS WITH THERMOELECTRIC HEAD ART. TE

Working temperature range

0 °C ÷ 100 °C

Room temperature

0 °C ÷ 60 °C

Max relative humidity

80%

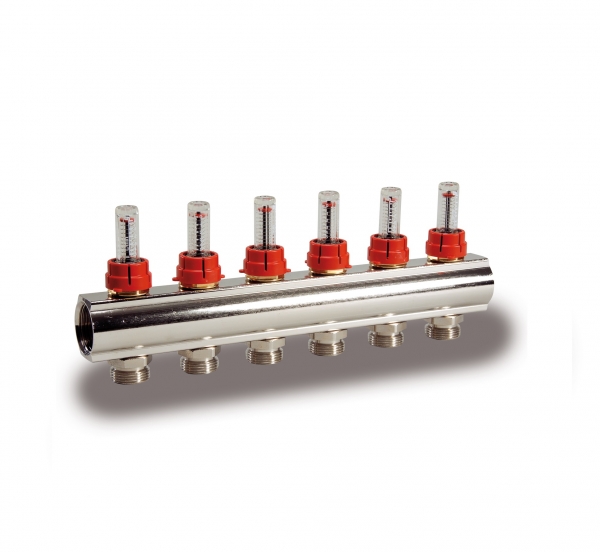

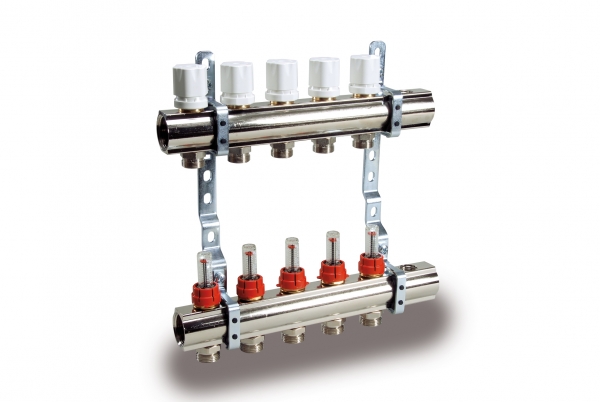

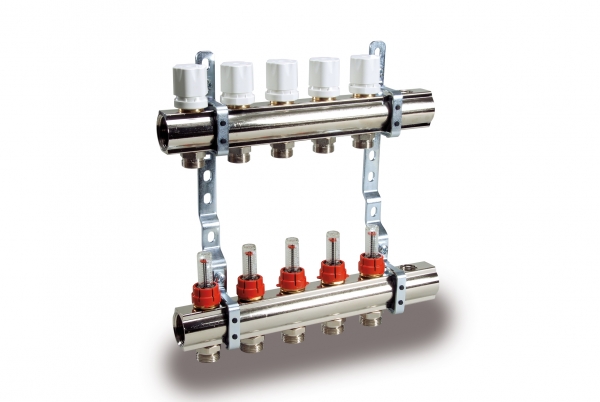

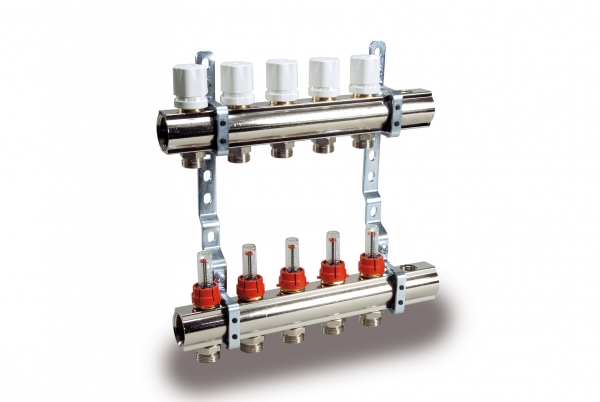

TECHNICAL SPECIFICATIONS WITH FLOW REGULATORS ART. TM 4012

Max temperature

70 °C

Max pressure

6 bar

Copper pipe

W 24x19 - TR 91

G 3/4 EK - TR 91/A

Plastic pipe

W 24x19 - TP 95

G 3/4 EK - TP 98

Multilayer pipe

W 24x19 - TP 97

G 3/4 EK - TP 99

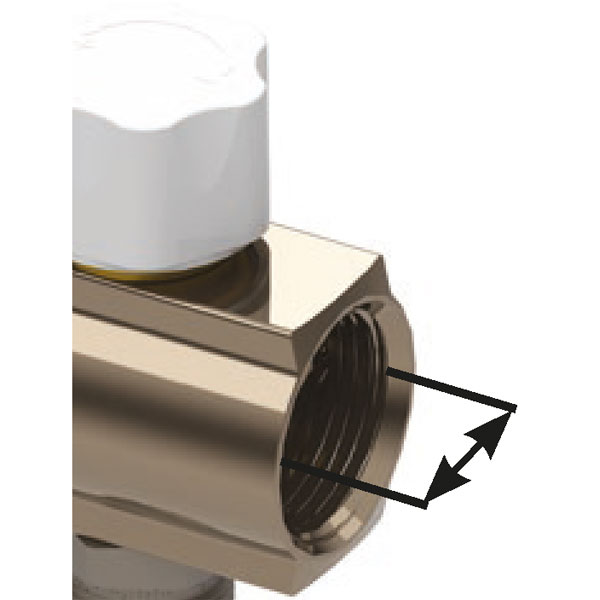

MAIN BODY CONNECTION

G 3/4

G 1"

G 1"1/4

CENTRE TO CENTRE DISTANCE

| G 3/4 | 40 mm | |

| G 1" | 50 mm | |

| G 1"1/4 | 50 mm |

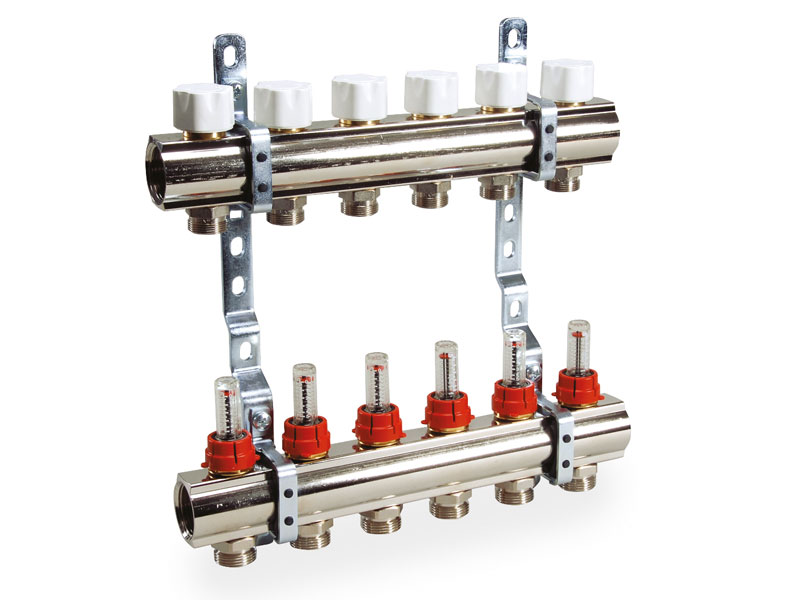

FLOW REGULATORS AND HOLDERS

With regulators and flow meters TM 4012, adjusting and balancing manifolds allow for an immediate verification of the system’s balance by reading the flow rate. This adjustment can be locked through a block cap. The glass and the measuring spring can be disassembled for maintenance and cleaned while the system is operating. This kind of manifold must be installed on the inlet.

LOCKSHIELD VALVE

Adjusting and balancing manifolds (lockshield type) feature a double micrometric adjustment with memory of position in case of temporary shutdowns and can be mounted both on inlets and outlets of the system.

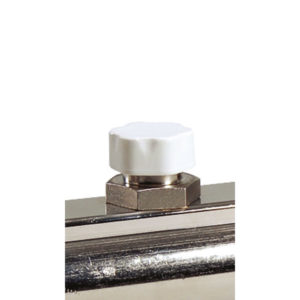

CONVERTIBLE HEADWORK

The tightening device on the stem of the manifolds with built-in valves for thermoelectric adjustment can be inspected and replaced while the system is operating. The control stem is in AISI 316 stainless steel and its tightness is ensured by two peroxide cured EPDM o-rings.

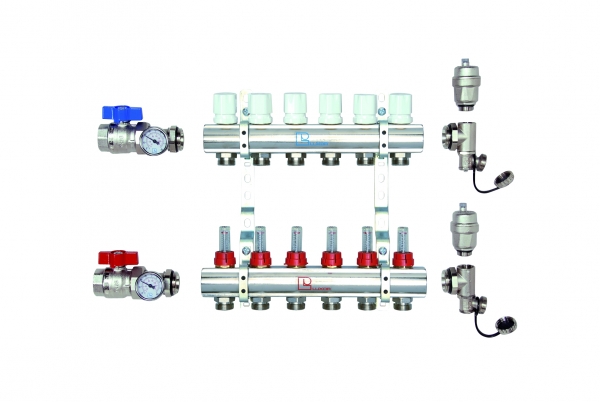

CD 474

G 1” x G 3/4 EK

10, 11, 12, 2, 3, 4, 5, 6, 7, 8, 9

CD 1474

G 1” x (W24x19)

10, 11, 12, 2, 3, 4, 5, 6, 7, 8, 9

CD 448

G 1” x G 3/4 EK

10, 11, 12, 2, 3, 4, 5, 6, 7, 8, 9

CD 449

G 1” x (W24x19)

10, 11, 12, 2, 3, 4, 5, 6, 7, 8, 9

CD 1446

G 1” x G 3/4 EK

10, 11, 12, 2, 3, 4, 5, 6, 7, 8, 9

CD 1466

G 1” x (W24x19)

10, 11, 12, 2, 3, 4, 5, 6, 7, 8, 9

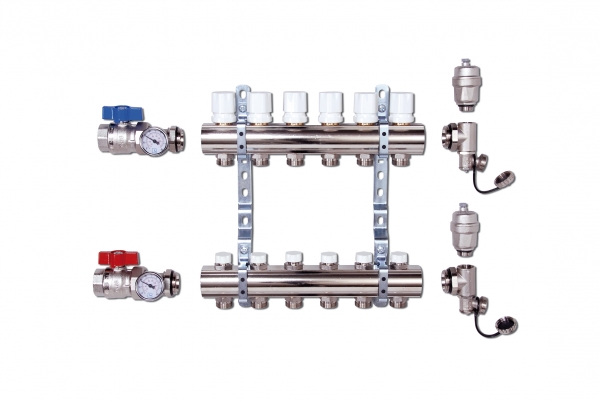

CD 473M

G 1”1/4 x G 3/4 EK

Nickel plating

CD 478M

G 1”1/4 x (W24x19)

Nickel plating

CD 468M

G 1” x G 3/4 EK

Nickel plating

CD 465M

G 1” x (W24x19)

Nickel plating

CD 1877

Yes

G 1”1/4 x G 3/4 EK

CD 1879

Yes

G 1”1/4 x (W24x19)

CD 477

Yes

G 1” x G 3/4 EK

CD 479

Yes

G 1” x (W24x19)

CD 1873

G 1”1/4 x G 3/4 EK

Nickel plating, Yellow

CD 1878

G 1”1/4 x (W24x19)

Nickel plating, Yellow