A flexible hose may seem like a minor component in a plumbing or heating system. However, it is actually one of the most critical elements for ensuring the system’s overall safety and efficiency.

Even a minor manufacturing defect can cause water leaks, damage to domestic or industrial environments and costly maintenance work.

At Luxor, our flexible hose production process is designed from the outset with one clear objective: to guarantee high performance in terms of safety, sealing and long-term reliability.

The importance of sealing in flexible hoses

When it comes to flexible hoses for plumbing and heating systems, the concept of hydraulic sealing plays a central role.

Even if correctly installed, a flexible hose must be able to maintain its performance over time, without structural failure or leaks.

This is particularly important for permanent installations in residential, commercial and industrial settings, where uninterrupted operation is crucial.

At Luxor, we have invested in patented technologies to ensure that each hose meets the highest quality and regulatory standards.

Luxor’s patented technology: UV paint for quality control

One of the features that distinguishes Luxor hoses is the use of patented UV paint, which automatically detects any defects during the assembly process.

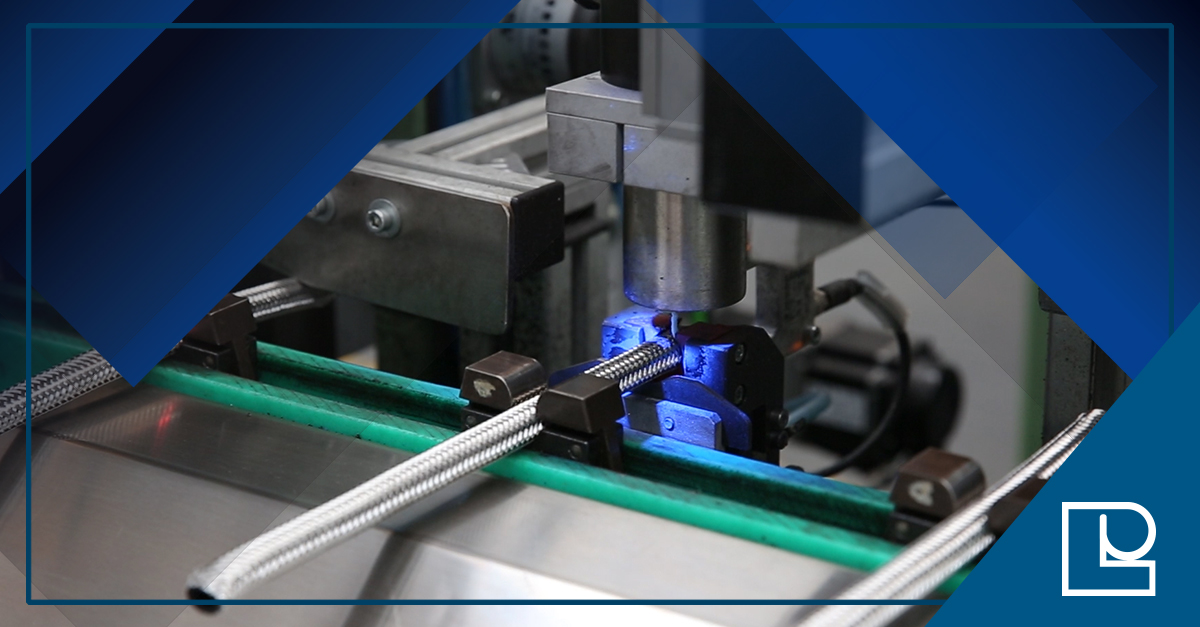

A fundamental step is carried out inside the special automatic assembly machines during production.

Transparent UV-reactive paint is applied to the metal braid in the area intended for the clamping sleeve before the fitting is inserted.

During the automated quality control phase, the tube is illuminated with UV light: if the paint is still visible, it means that the braid has not been correctly inserted into the sleeve, compromising the integrity of the connection.

In this case, the hose is automatically discarded.

What is the result? Only hoses that are perfectly assembled, with correctly inserted braiding and guaranteed hydraulic sealing, pass the inspection and reach the market.

A production process that prioritises safety

UV marking is just one of the many control stages that every Luxor flexible hose must pass through before leaving our plants.

- All our processes are designed to guarantee:

- maximum product tightness and safety;

- no structural defects or assembly errors;

- durability over time, even under high pressure or temperature conditions;

- compliance with international standards.

Every detail is taken care of in-house, from design to production to final testing.

This enables us to provide installers and OEMs with a reliable product for any application.

Luxor flexible hoses: the safe choice for every system

The reliability of a system starts with its components.

With Luxor flexible hoses, you can be sure you are using a product that combines patented technology, rigorous quality control and Italian know-how.